BindEx Machinery Appeared in the Printing and Packaging Hi-tech Exhibition: Smart Factory Solutions Leading the Future of the Post-press Industry

2024-09-26

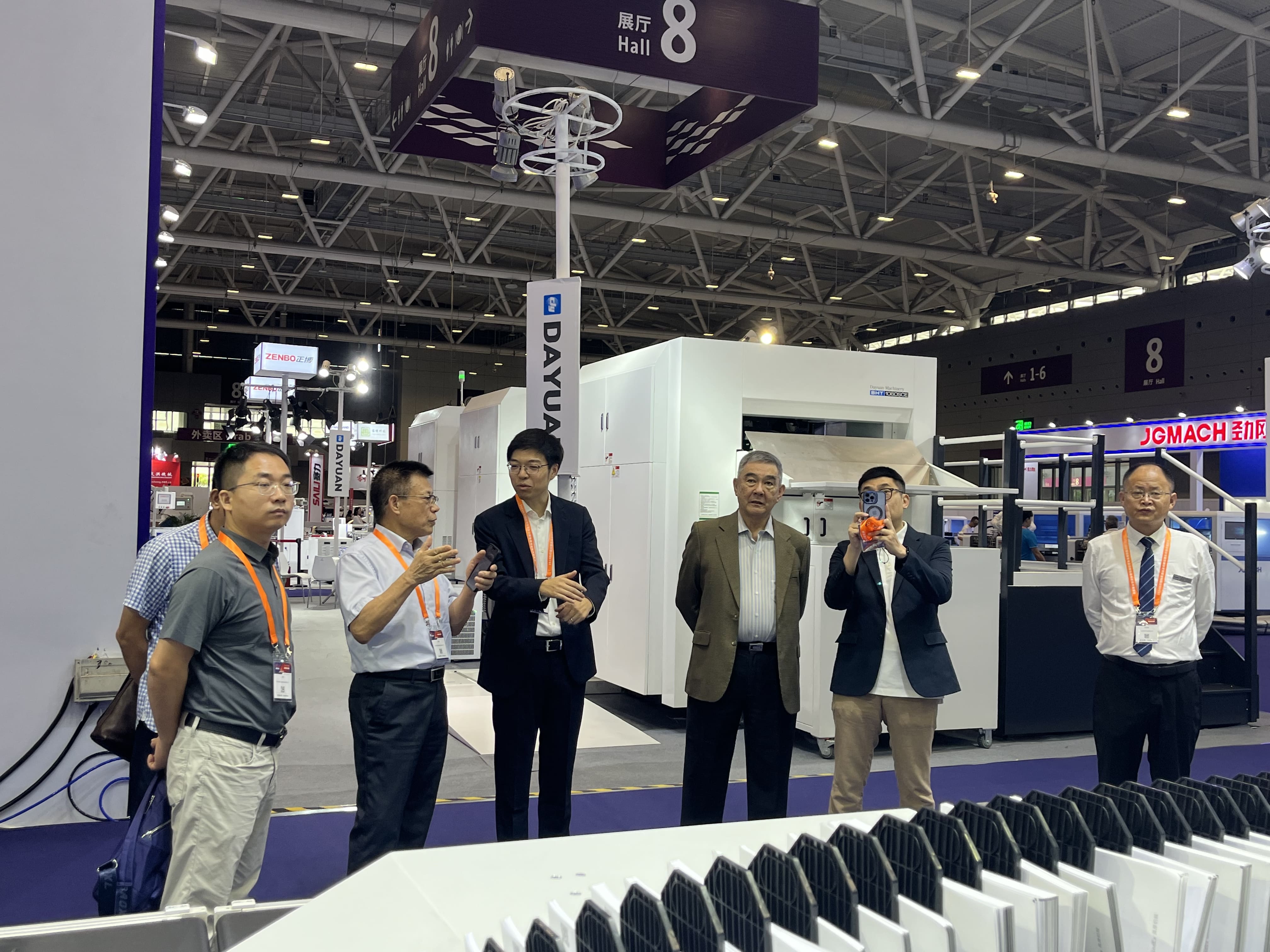

On September 26th, the Printing and Packaging Hi-tech Exhibition concluded successfully in Hall 8 of Shenzhen World Exhibition & Convention Center (Bao'an). BindEx Machinery made a splendid appearance at the exhibition, continuing its dedicated research and development since Drupa, showcasing the latest innovations and technological advancements, attracting extensive attention from industry experts and customers. There were quite a number of highlights at this exhibition, particularly our launch of the digital post-press Lights-out Factory, unmanned binding production line, and smart factory solutions, marking a significant step towards intelligence and automation in the printing industry.

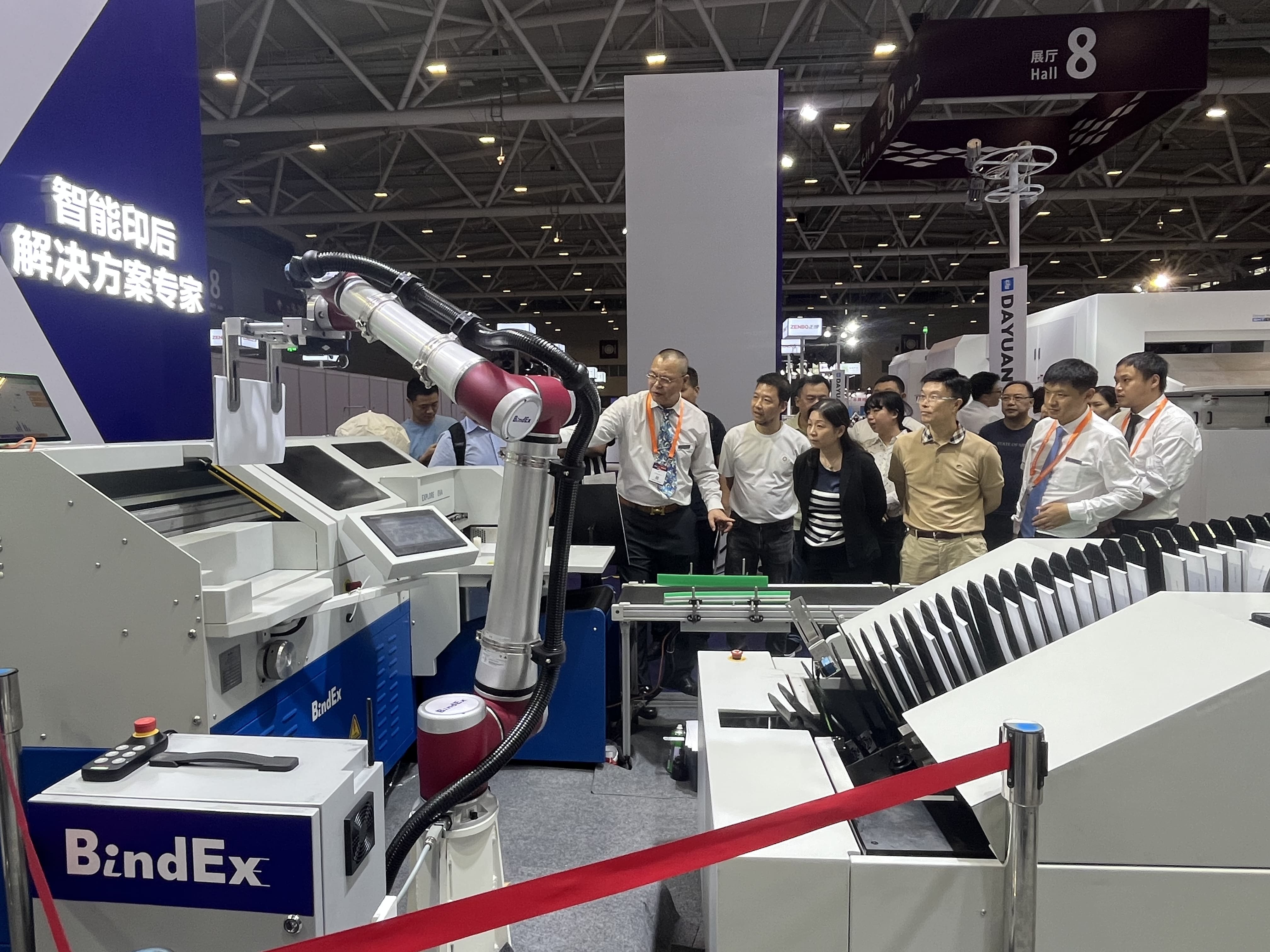

■ Lights-out Factory: A new level of unmanned production

During the exhibition, the concept of the "Lights-out Factory" attracted the attention of numerous visitors. The brand-new EXPLORE binding machine features an innovative fully automatic PUR/EVA solution, catering to various needs of short-run binding, long-run binding, and print-on-demand, with characteristics such as easy operation, quick format conversion, and low maintenance costs. This equipment can be optionally equipped with a patent-protected PUR glue spraying system or an EVA gluing system, and it also has an AI interface that allows it to connect with robotic arms, feeders, digital three knife trimmers, and other equipment to form an automated binding production line.

With fully automated workflow, we can achieve efficient post-processing and significantly enhance production efficiency and product quality. The unmanned binding solution exhibited this time is one of the best practices of the Lights-out Factory concept. Through a highly integrated intelligent control system, these devices can complete all operations such as book format changing, inspection, binding, and cutting without human intervention, demonstrating the future of post-press processing moving towards unmanned production.

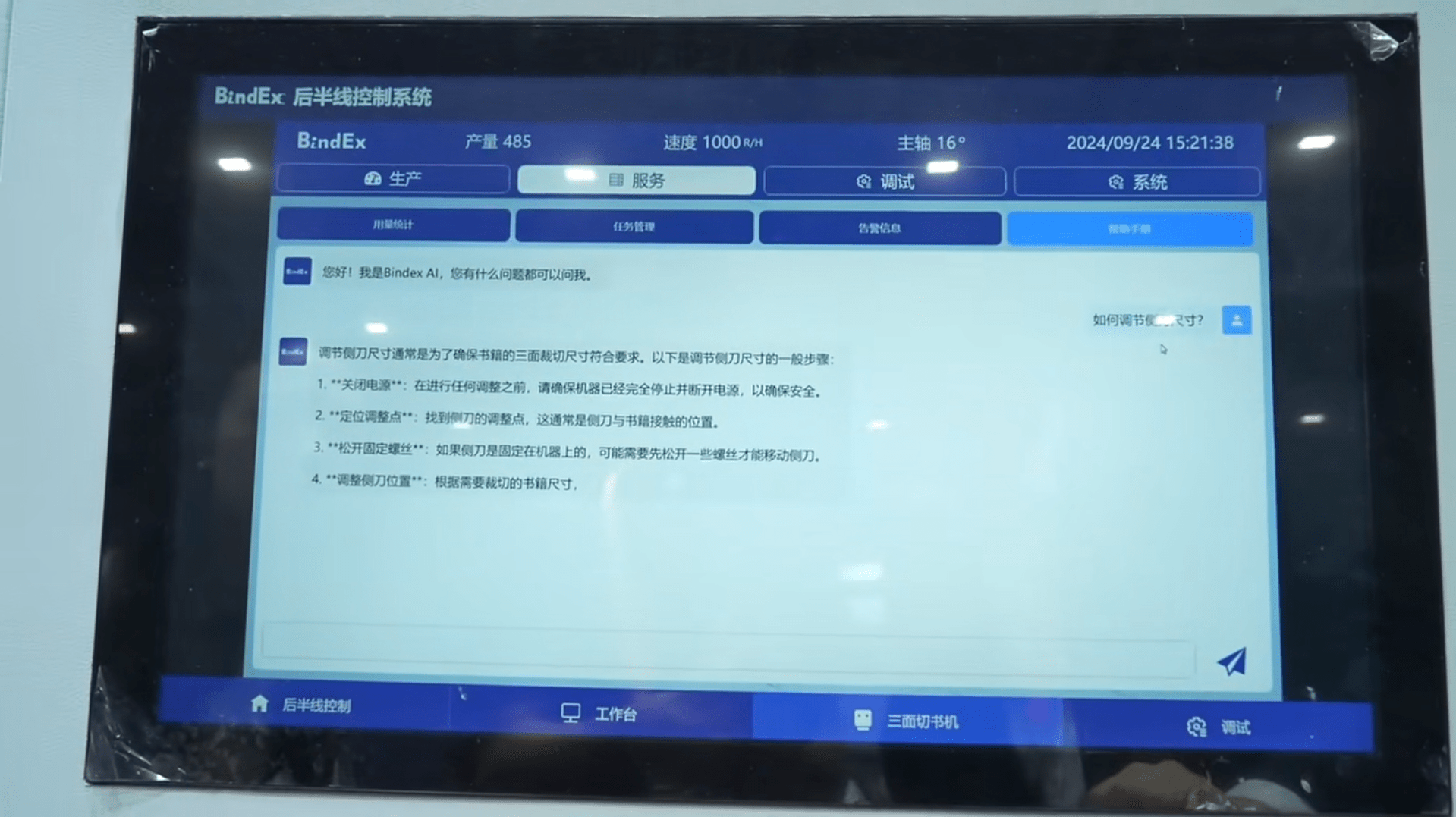

■ Man-machine dialogue: A new paradigm for AI application

Man-machine dialogue was undoubtedly another major highlight of this exhibition. By integrating AI technology, the equipment can automatically search for answers based on users' questions. The ingenious use of AI not only significantly improves work efficiency and reduces operational difficulty but also responds instantly to users' requests, provides suggestions for fault diagnosis and other operational aspects, reduces the risk of operational errors, and offers highly competitive solutions for post-press processing enterprises.

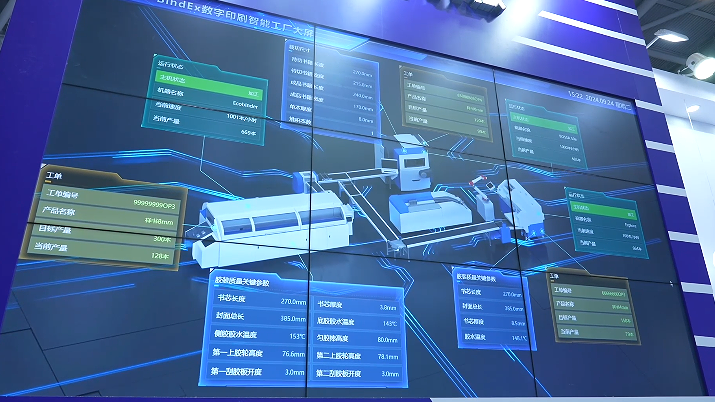

■ Smart factory solutions: A new breakthrough in digital transformation

At this exhibition, BindEx Machinery also highlighted its smart factory solutions. This solution features real-time data collection and equipment linkage, enabling digital management of every detail in the production process. This not only improves production efficiency but also reduces operating costs. After experiencing this system during the exhibition, customers all commented that its powerful data analysis capabilities and predictive functions will provide strong support for their production decisions.

During the exhibition, our team had in-depth exchanges with multiple potential clients and gained valuable market feedback and cooperation opportunities. BindEx Machinery will continue to focus on technological research and innovation, planning to launch more intelligent and digital equipment in the future to meet the ever-changing market demands. We look forward to working hand in hand with all partners to jointly promote the sustainable development of the post-press industry!